In the chemical and pharmaceutical industries, pipeline design plays a critical role in ensuring safe fluid transfer, consistent process performance, and strict contamination control. While straight glass pipes are suitable for linear flow, most real-world process systems involve direction changes, elevation shifts, and complex layouts. Achieving this without disturbing flow behavior or product integrity requires specialized components—this is where glass bends become essential.

Glass bends are widely used in chemical plants, pharmaceutical manufacturing units, distillation setups, and laboratory pipelines where chemical resistance, high purity, and visual monitoring are non-negotiable.

In this blog, we’ll explain what a glass bend is, how it works in pipelines, its benefits, key industrial applications, and why choosing the right manufacturer like Jeshal Glass Work matters.

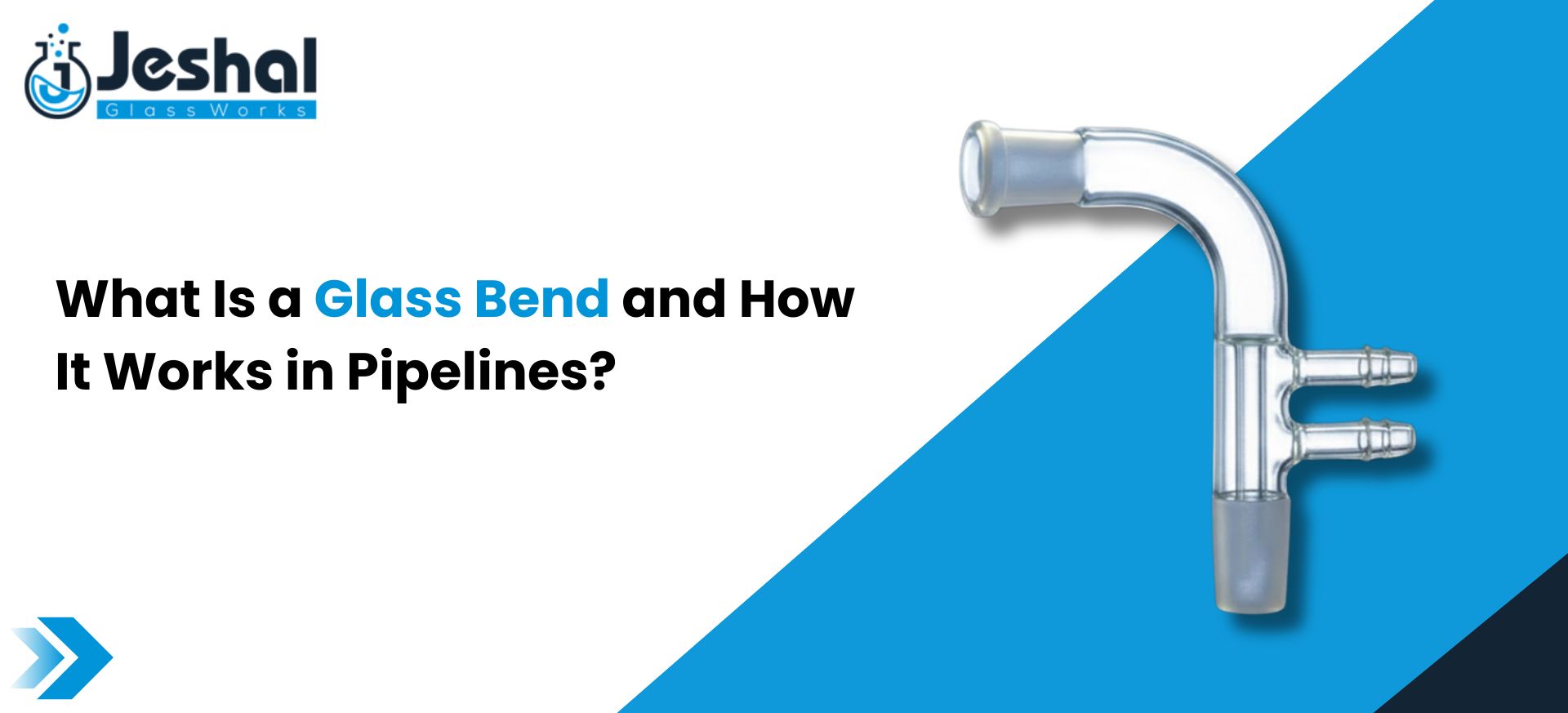

A glass bend is a curved glass pipe component designed to change the direction of fluid or gas flow within a pipeline system. These bends are typically manufactured from borosilicate glass, a material known for its excellent chemical resistance, thermal stability, mechanical strength, and transparency.

Glass bends are produced in various standard and custom configurations, including:

In chemical and pharmaceutical pipelines, glass bends are preferred because they allow smooth flow redirection while maintaining system cleanliness and enabling visual inspection throughout the process.

Glass bends work by redirecting the flow of liquids, vapors, or gases along a curved path without causing sudden pressure drops or excessive turbulence. When properly designed and installed, they maintain consistent flow velocity and minimize stress on the pipeline system.

In chemical and pharmaceutical environments, glass bends are commonly integrated into:

One of the biggest functional advantages of glass bends is transparency. Operators can visually monitor flow behavior in real time, identify blockages, detect crystallization, observe phase changes, and spot contamination early. This level of process visibility is impossible with metal or opaque piping systems.

Glass bends are widely used across multiple process industries due to their unique combination of purity, visibility, and chemical resistance.

Selecting the right glass bend is crucial for system safety, performance, and longevity. Important factors include:

Working with an experienced and reliable manufacturer ensures that glass bends meet precise technical and operational requirements.

Jeshal Glass Work is a trusted manufacturer of precision-engineered glass bends for chemical, pharmaceutical, and laboratory pipelines. With a strong focus on quality, accuracy, and customization, Jeshal Glass Work delivers solutions that meet demanding industrial standards.

Key advantages include:

Jeshal Glass Work’s expertise ensures glass bends that support process safety, operational efficiency, and long-term reliability.

A glass bend is a vital component in chemical and pharmaceutical pipelines, enabling smooth direction changes while maintaining purity, safety, and full process visibility. From laboratory setups to large-scale distillation and solvent recovery systems, glass bends play a key role in achieving efficient and controlled fluid transfer.

Choosing the right glass bend—and the right manufacturer—can significantly enhance pipeline performance and process reliability.

Looking for high-quality, custom glass bends for your chemical or pharmaceutical pipelines? Contact Jeshal Glass Work today for expert guidance and dependable glass solutions tailored to your process needs.

Glass is non-reactive, chemically resistant, and allows full visual monitoring, ensuring high purity and process control in pharma manufacturing.

It redirects flow along a curved path, reducing turbulence and allowing operators to visually monitor the process inside the pipeline.

Most glass bends are made from borosilicate glass due to its strength, transparency, and resistance to heat and chemicals.

Yes, glass bends can be manufactured in various angles, diameters, and shapes to suit specific pipeline designs.

Jeshal Glass Work manufactures precision glass bends with custom options for reliable performance in industrial pipeline systems.